9000+ Cashless Garages

1.2 Cr+ Policies Sold

Car insurance Online, Up to 90% Discount

It's a Brand New Car

What is a Leaf Spring Suspension System: Types, Working and Advantages

As the name suggests, a leaf spring suspension is a simple collection of leaf-looking springs stacked on top of one another. They are widely used in suspension systems of heavy and light commercial vehicles.

Read on to learn more about leaf spring suspension systems as the following sections mention the parts, types and uses of a leaf spring suspension system.

What is a Leaf Spring Suspension System in Vehicles?

A simple type of suspension consisting of steel layers of varying thicknesses that is layered on top of one another is called a leaf spring. A leaf spring suspension system is one of the oldest types of springs, which are extremely useful in trucks and other heavy-load-carrying vehicles.

What is the Importance of a Leaf Spring Suspension System?

A leaf spring suspension system does its job by providing comfort to the passengers. It does so by minimising the vertical vibration caused by the nonuniformity of road geometry.

Many things can happen if a vehicle's load weight is too high. There's a chance that your car or trailer will begin to wobble more or bounce more. Should this be the situation and the car being pulled weighs too much, there can be a suspension issue. However, a leaf spring suspension system helps combat such issues.

What are the Parts of a Leaf Spring Suspension System?

A leaf spring suspension system is made up of several parts. They include:

- Metal plates or leaves

- Master leaf

- Centre bolt

- U-bolt

- Rebound clip

- Spring eye

- Shackle

- Rubber bush

What are the Types of Leaf Spring Suspension Systems?

There are multiple types of leaf spring suspension systems, such as:

1. Multi-Leaf Spring

This consists of more than one spring or metal plate. These plates are kept on top of each other, with the largest one on top. A centre bolt is placed through the thickest part to keep the plates in shape. The structure of the plates helps the vehicle reach stability.

2. Mono Leaf Spring

This is a fancy plate with no supporting leaves around. They are made with a single metal piece, which is typically used as a replacement to the traditional leaf spring systems. They are thicker in the centre and get narrower towards the edges.

3. Semi-Elliptical Leaf Spring

Depicting a look similar to that of a bow and arrow, they are the most common types of leaf spring suspension system. The structure helps endure vibrations caused by bumpy roads, providing a comfortable and quiet ride.

4. Quarter-Elliptical Leaf Spring

This older leaf spring type looks similar to a standard leaf. The only difference is that it is divided into half. They are constructed similarly to semi-elliptical leaf springs, however, they are typically used in older vehicles.

5. Three-Quarter Elliptical Leaf Spring

By joining a semi-elliptical and quarter-elliptical leaf spring, you can form a three-quarter elliptical spring. This component provides additional support and is commonly found in older vehicle models.

6. Full Elliptical Leaf Spring

This is a combination of semi-elliptical leaf springs that are joined facing each other to form a full elliptical shape. Their inability to maintain correct axle alignment has made them outdated.

7. Transverse Leaf Spring

They look like semi-elliptical springs, with the only difference being they are kept face down. Thus, the longest leaf stays at the bottom. They are often installed in older models.

How Does a Leaf Spring Suspension System Work?

Discussed below is the working process of a leaf spring suspension system:

- The blades, or several leaves, make up the leaf spring. There are eyeballs on the end of the longest blade. This is referred to as the master leaf. Steel straps are used to secure each blade to its companion.

- The axle spring, either front or rear, is supported by a U-bolt. A simple pin is used to place the one end of the spring on the frame, and a shackle is used to connect the other end.

- The wheel rises and deflects the spring when the car encounters an obstacle on the pavement. The space in between spring eyes is altered, consequently. The spring won't be able to adapt to this variation in length if both ends are fixed.

- This is accomplished by using a flexible connection at one end, a shackle. The leaf develops a gentle springiness with a compressed shackle because it has a greater inclination to spring.

What are the Advantages of a Leaf Spring Suspension System?

- These springs offer a reliable and easy way to handle big loads.

- Leaf springs offer an excellent damping effect and are lightweight.

- More weight can be supported by it than by helical springs.

- It acts as a solid link between the frame and the axle in addition to being a suspension component.

- It is one of the least expensive suspension system options for heavy-duty commercial trucks.

- It provides the option of simple repair, particularly when dealing with multi-leaf springs.

What Are the Disadvantages of a Leaf Spring Suspension System?

- They are heavy and are not easy to install.

- The interleaf friction leads to poor drive comfort.

- With time, the springs can wear out and sag. When the springs sag unevenly, it can alter the vehicle’s cross weight, affecting the overall handling.

The primary purpose of a leaf spring suspension system is to support the heavy weight of a vehicle. Through its construction, it helps create a smooth ride and provides optimal handling efficiency. Therefore, it is crucial to keep an eye out for this system and ensure all the components are working properly.

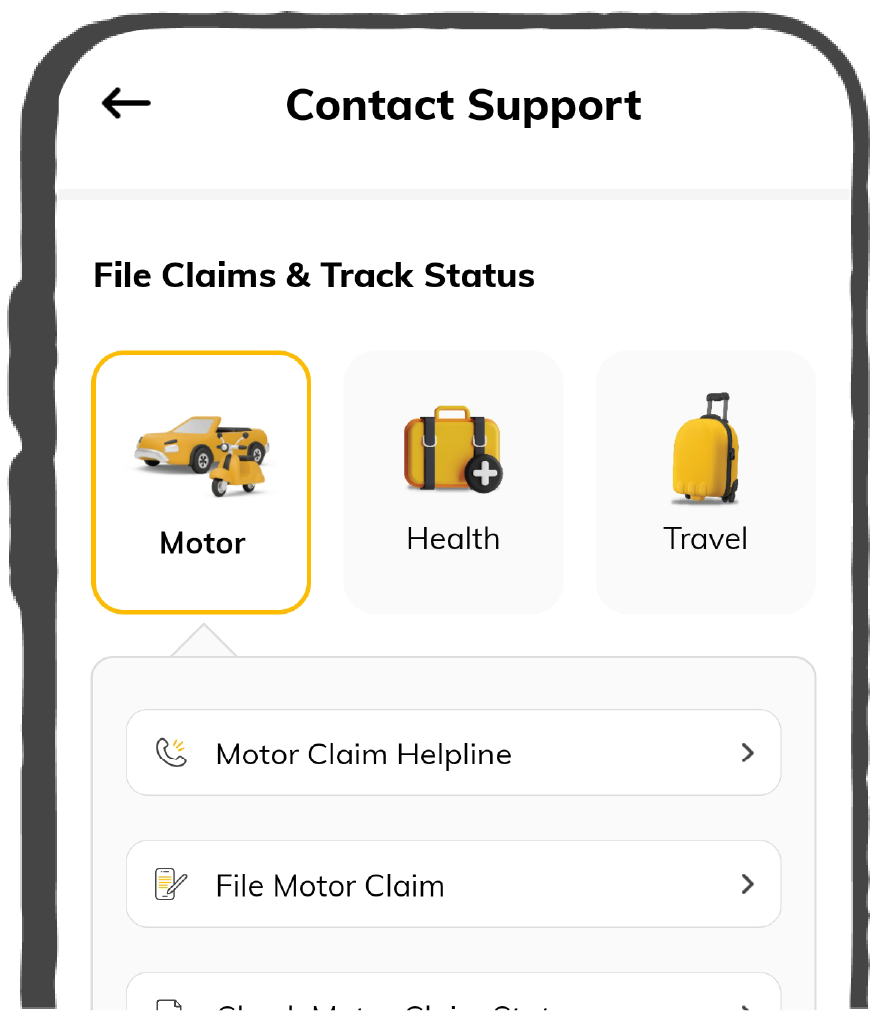

Explore Insurance Coverage for Your Vehicle