9000+ Cashless Garages

1.2 Cr+ Policies Sold

Car insurance Online, Up to 90% Discount

It's a Brand New Car

What is a Piston in Engine and How Does it Work?

Pistons are an important part of internal combustion engines. Hence, the latter are often referred to as ‘piston engines.’ Besides converting the energy released during combustion into mechanical energy, this key component performs other functions as well.

In this piece, we’ll cover everything from how pistons are made, parts of a piston, functions, and types.

Table of Contents

What is a Piston?

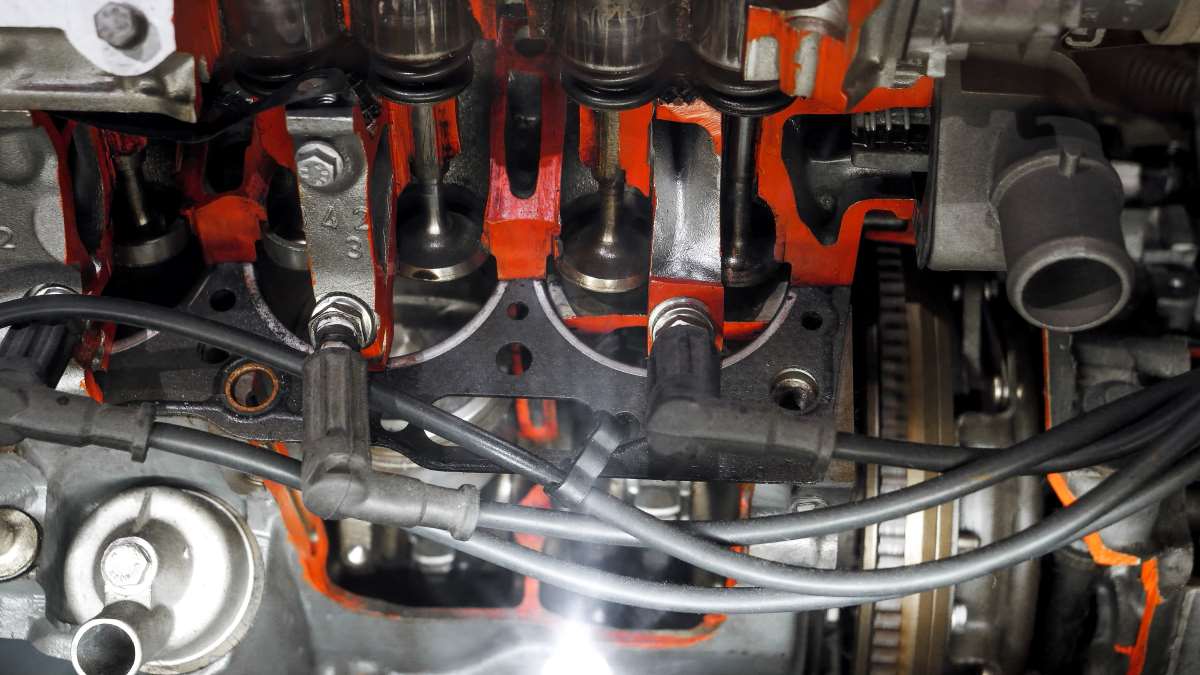

A piston is a crucial component of various reciprocating machinery, such as gas compressors, hydraulic and pneumatic cylinders, pumps, and engines. The piston rings provide a gastight seal within the cylinder containing the moving component. Its function in an engine is to transmit the force of the expanding gas in the cylinder to the crankshaft through a connecting rod and/or piston rod.

The crankshaft is linked to the piston with a connecting rod. When the piston rises and falls, the connecting rod and crankshaft turn the crankshaft, which rotates the wheels. Most cars have four, six, or eight cylinders, but some have twelve. Steam engines, which use boiling water to move pistons in cylinders outside the engine, use them.

As the piston rises and falls in the cylinder, the fuel-air mixture compresses, starting the spark plug ignition process. The explosion pushes the piston down, releasing exhaust gases through the exhaust system.

How Does a Piston Work in an Engine?

Here is a step-by-step explanation of how a piston works:

- Step 1: As the engine runs, the piston moves up and down in the cylinder. At the turning point, it experiences speed changes.

- Step 2: The change in speed - first slowing down and then accelerating again leads to inertia forces acting on the piston. When combined with the gas pressure, these forces create the piston force.

- Step 3: As a next step, piston force is transferred to the connecting rod and crankshaft, which converts it into rotational motion.

- Step 4: The force from expanding combustion gases pushes the piston, leading to the crankshaft's rotation. Ultimately, the motion is transmitted through a system of gears, effectively transferring the power generated by the piston.

What Are Pistons Made Up Of?

In modern engines, pistons are primarily made of aluminium alloys owing to their lightweight nature and efficiency. While most pistons are cast, some might be forged to enhance strength and fatigue life.

Piston rings, on the other hand, are predominantly made of cast iron or steel alloys. The ring package comprises a wiper ring, a compression ring, and an oil ring.

What Are the Major Parts of a Piston?

Let’s dig deeper into the major parts of a piston and its functions.

1. Piston Rings

Typically made of cast iron and alloy cast iron, piston rings play an important role in engine operation. They serve the most important function of minimising friction between the piston and cylinder walls and preventing gas from leaking in the combustion process.

There are two main types of piston rings - Compressor rings, which seal the compression chamber, and oil control ring which helps regulate oil consumption.

2. Piston Head/Crown

Located just above the piston, it is the part that comes in contact with the combustion gases, making it experience high temperature and pressure.

3. Piston Skirt

The piston skirt refers to the cylindrical portion of the piston that travels within the cylinder. They are intentionally roughened during manufacturing to retain lubrication and withstand thrust.

4. Piston Pin

Also referred to as a gudgeon pin, this pin connects the piston to the connecting rod. They are made up of harder steel in order to offer good tensile strength.

5. Connecting Rod

The role of connecting rod is to connect the piston to the crankshaft. This allows piston movement within the cylinder and subsequently transmits motion to the engine. The connecting rod is made using cast aluminium alloy and is designed in a manner to withstand piston movement.

6. Connecting Rod Bolt

The primary role of the bolt is to secure the connecting rod to the crankshaft.

7. Piston Bearings

Piston bearings or wrist pin bearings provide support and reduce friction between the piston pin and connecting rod, thus enhancing engine performance and longevity.

What Are the Different Types of Pistons?

While there are many different types of pistons, when it comes to piston shapes, these are the notable ones:

- Flat-top Pistons: As the name suggests, a flat-top piston boasts a flat-top surface. They have the smallest amount of surface space, enabling them to provide efficient combustion.

- Dish Pistons: The shape of dish pistons resembles a plate with slightly curled-up outer edges. It is commonly used in boosted applications that do not require high compression ratios.

- Dome Pistons: Dome pistons feature a raised centre for increased surface area and reduced compression, allowing for efficient energy performance.

What Are the Important Functions of a Piston?

The primary role of the piston is to transfer energy by receiving the force generated by the combustion gases within the cylinder. The energy is thereafter transmitted from the connecting rod to the crankshaft.

Additionally, the piston plays an important part in dissipating the heat generated during combustion by transferring it to the cylinder walls.

Overall, the functions of a piston include:

- Energy Transfer: Applying pressure to molecules of gas or liquid facilitates the transformation of that pressure into usable energy in motion. Different air pressures caused by the piston's motions turn the crankshaft, generating the force that drives the vehicle forward.

- Heat Dissipation: Heat transmission from burned gas is significantly higher than in any other cycle phase. Heat transfer degrades engine performance. Convective heat transfer is influenced by gas temperature, heat transfer coefficient, charge motion, and transfer area, which are influenced by flame/combustion chamber geometry.

- Supporting Piston Rings: The potential damage caused by the piston slamming into the cylinder is averted by using piston rings. These rings, with their tension properties, ensure a tight seal, preventing the catastrophic failure that could result from the piston's uncontrolled movement.

- Guiding the Connecting Rod: The piston, piston pin, and connecting rod form a precision-engineered assembly, translating the piston's linear motion into the crankshaft's rotational motion. When functioning in perfect coordination, this intricate system ensures the engine's smooth operation, with the piston lifting the connecting rod and turning the crankshaft as it rises in the engine.

What Are the Properties of a Good Piston?

A good piston must possess the following properties:

Strength and Durability: To avoid breaking under the strain of the power stroke, it must be able to endure high pressure and temperatures.

Lightweight: A lightweight piston helps improve engine efficiency and reduces inertia forces.

Low Heat Expansion: During operation, the piston's design should minimise the impact of thermal expansion.

Balanced Design: The ideal piston design considers the crown shape, the design of the piston skirt, and other aspects to achieve a balance between the piston's weight, strength, and performance.

Thus, the piston is a key component of internal combustion engines. From withstanding high temperatures and pressures, it plays a crucial role in ensuring optimal engine performance and efficiency!

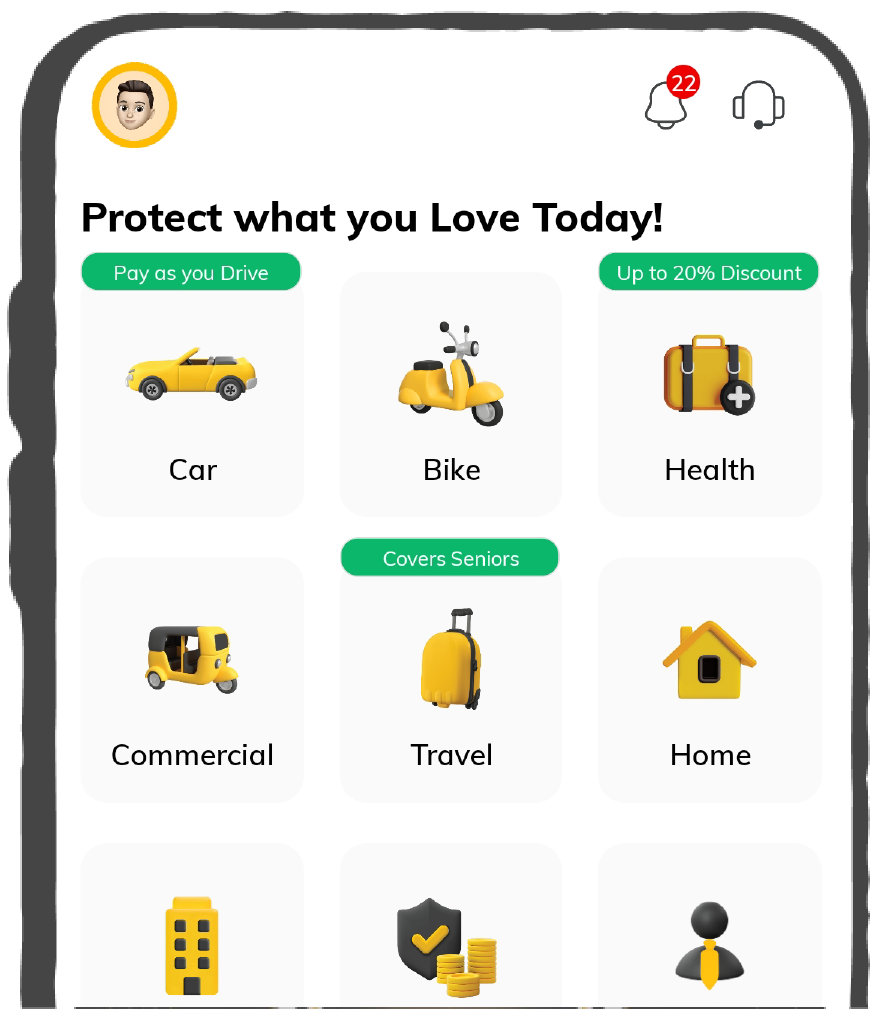

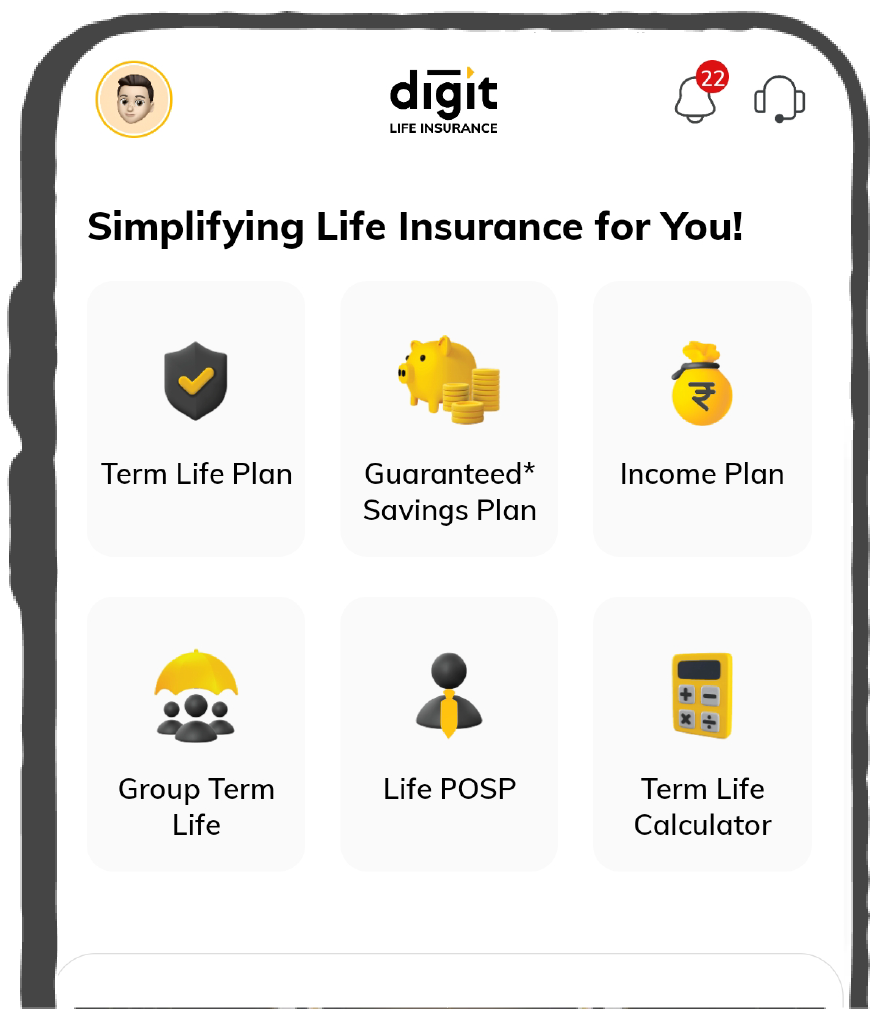

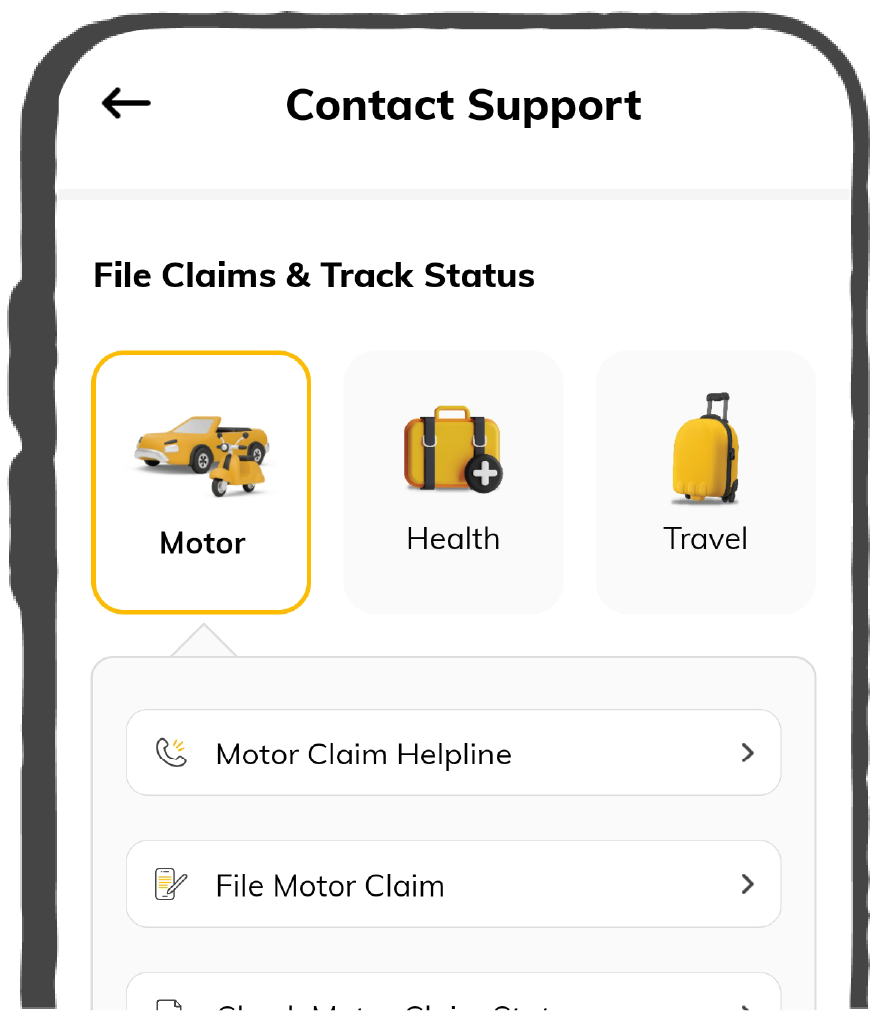

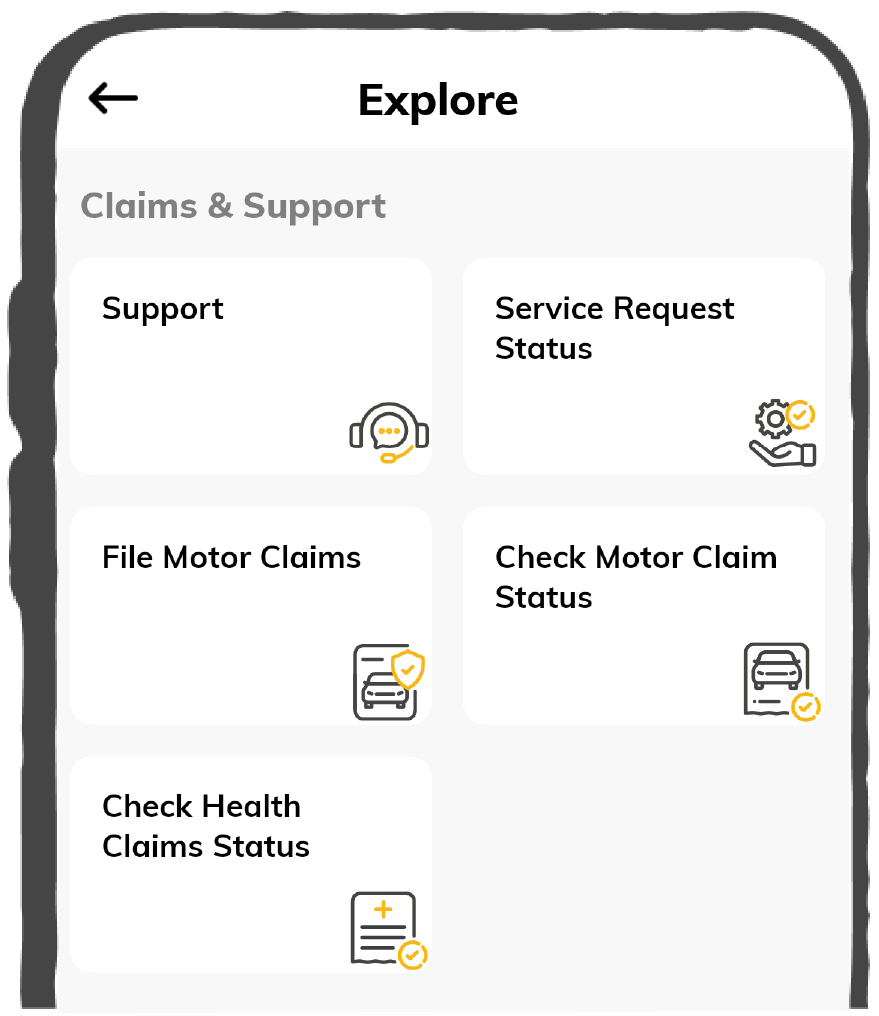

Explore Insurance Coverage for Your Vehicle