9000+ Cashless Garages

96% Claims Settled (FY 24-25)

Accessibility Options

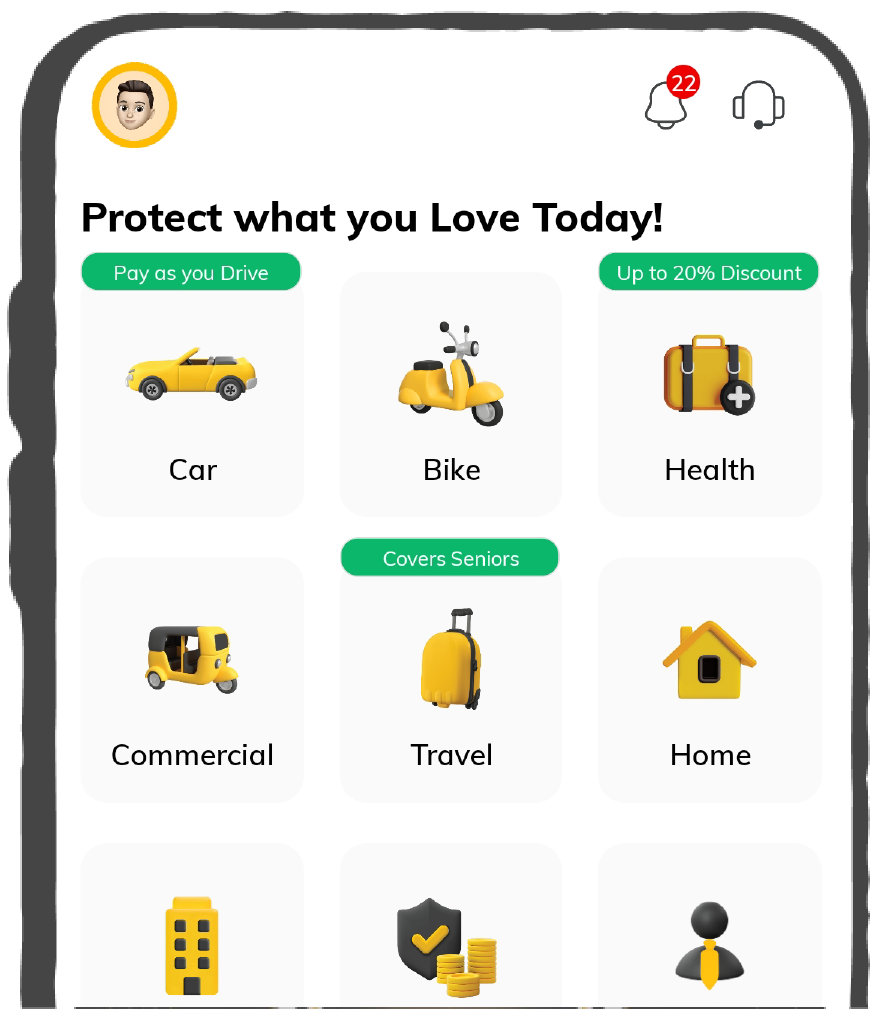

General

General Products

Simple & Transparent! Policies that match all your insurance needs.

37K+ Reviews

7K+ Reviews

Scan to download

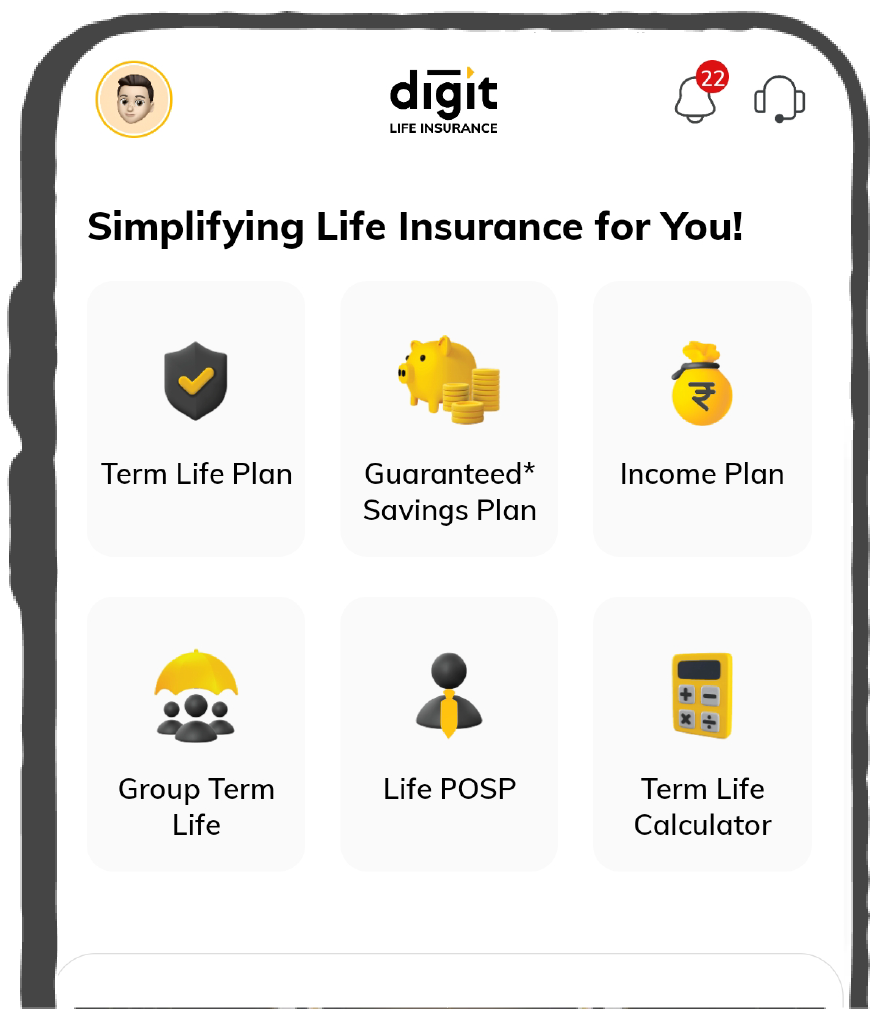

Life

Life Products

Digit Life is here! To help you save & secure your loved ones' future in the most simplified way.

37K+ Reviews

7K+ Reviews

Scan to download

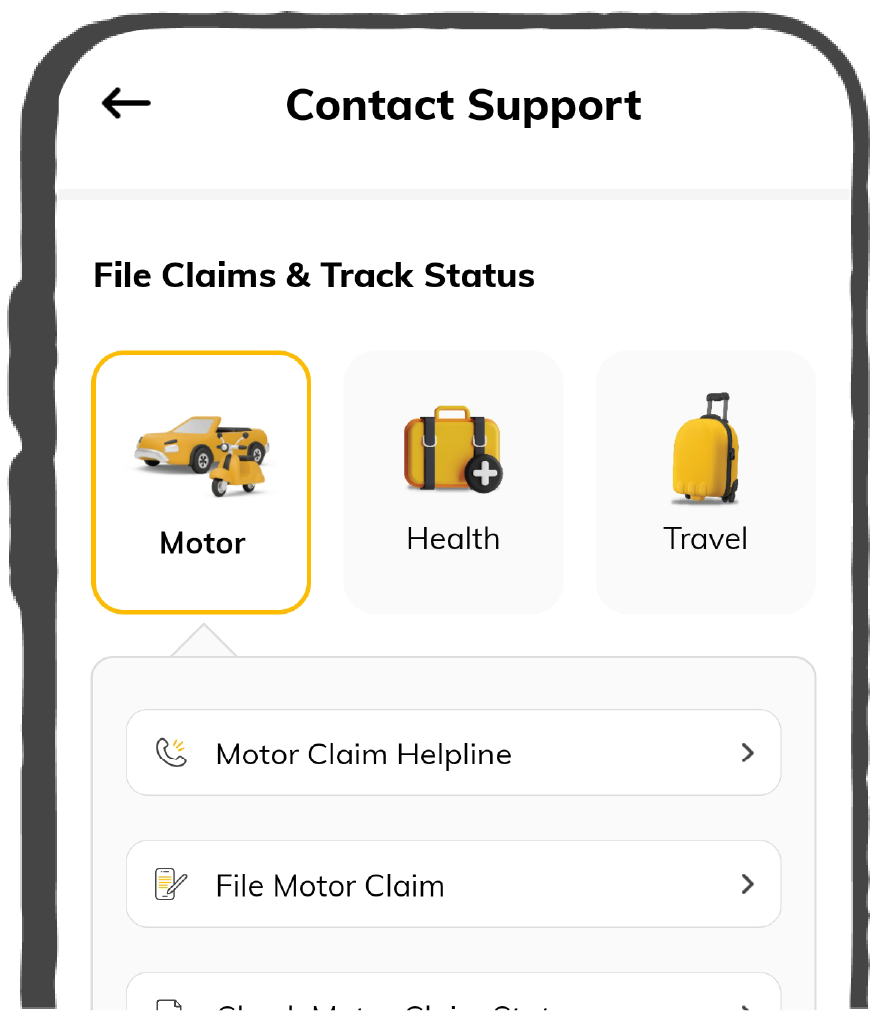

Claims

Claims

We'll be there! Whenever and however you'll need us.

37K+ Reviews

7K+ Reviews

Scan to download

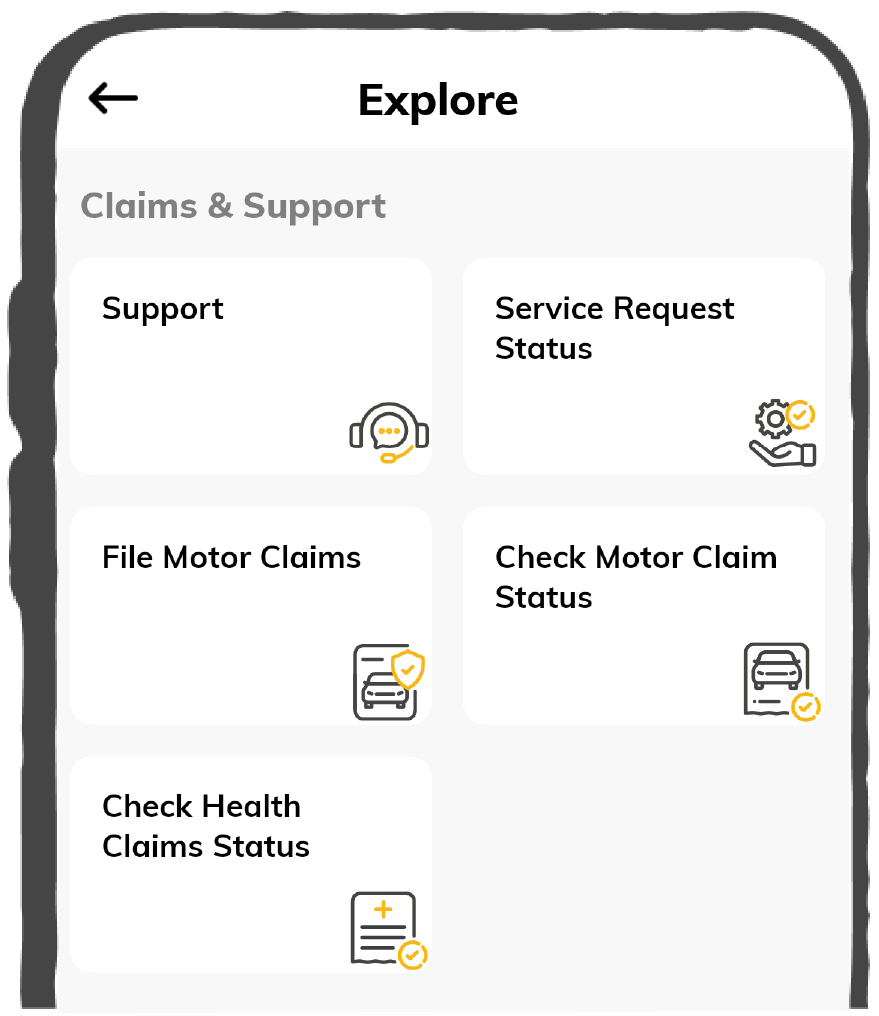

Resources

Resources

All the more reasons to feel the Digit simplicity in your life!

Tools & Calculators

Tools & Calculators

37K+ Reviews

7K+ Reviews

Scan to download

37K+ Reviews

7K+ Reviews

Select Preferred Language

Our WhatsApp number cannot be used for calls. This is a chat only number.

Enter your Mobile Number to get Download Link on WhatsApp.

You can also Scan this QR Code and Download the App.

9000+ Cashless Garages

96% Claims Settled (FY 24-25)

Sorry!

We are facing some issue in processing your request.

We require some time to check & resolve the issue.

SP code link generated is expired or invalid, please connect with your RM

Carbon fibre is a material made of carbon atoms. The atoms are very closely bonded within a minimal crystal structure. It is five times stronger than steel but significantly lighter. This is the reason that contributes to improving the speed, fuel use, and safety of cars.

Carbon fibre is robust yet very light. Meanwhile, aluminium provides excellent affordability and an impressive degree of flexibility. From fundamental differences between carbon fibre vs aluminium to benefits, this article is intended to help you make informed decisions.

Carbon fibre is a fibre drawn from thin strands of carbon atoms. The carbon fibres have been combined and bonded by a resin into a composite fabric. Such a composite is strong, has an excellent strength-to-weight ratio, and also rust-free.

The material is rugged and excels well in many industries. It is from the aerospace and automotive industries to equipment for sports. It is thus in demand for high-performance items like bicycles and racing cars, for which minimum weight and good strength are required.

Aluminium is a lightweight and ductile metal used in many industries, from automobiles to other products. One of the reasons it is popular is that it rarely rusts and is recyclable, besides being cheap. Aluminium bends and shapes relatively quickly. So it remains very popular when it has to make lots of things.

It is, in fact, cheaper compared to carbon fibre and, thus, used in structural parts, panels, and frames. However, it's not as strong as carbon fibre. Aluminium is a great, strong, and reliable choice for most car applications.

Although both carbon and aluminium are good, they have certain differences. The table below highlights the key attributes of carbon fibre and aluminium:

| Criteria | Carbon Fibre | Aluminium |

| Weight | Lighter than aluminium, enhancing acceleration, handling, and fuel efficiency performance. Ideal for high-performance vehicles. | Lightweight but heavier than carbon fibre. It still provides good fuel efficiency. It is commonly used in mass-market vehicles to balance weight and cost. |

| Strength | High tensile strength, offering excellent durability and resistance to stress. Perfect for high-end sports cars and performance vehicles. | Moderate strength, adequate for most automotive applications. Suitable for structural parts and body panels in everyday vehicles. |

| Corrosion Resistance | It also resists corrosion extraordinarily. It is, therefore, durable in rough environments. It is also ideal for long-term use in high-performance applications. | Excellent corrosion resistance when the material is coated. This makes it very suitable for many auto parts exposed to the elements. |

| Manufacturing Cost | It is expensive due to the complex manufacturing process and advanced technologies required for production. | Cost-effective for mass production. It is making it the preferred material for most mainstream car manufacturers. |

| Sustainability | Recycling is difficult, as its complex structure poses a long-term ecological impact. | It is recyclable; only 5% of the energy that goes into recycling puts it alongside new production. It can reduce the carbon footprint by allowing recycling infinitely. |

| Applications | It is mainly used for high-performance cars, luxury sports, and unique applications. Thereby used where weight reduction and strength are uncompromisable. | Widely used in all structural parts, panels, and mass production. |

The main advantages and disadvantages of carbon fibre used in car manufacturing are presented in the following points:

| Advantages of Carbon Fibre | Disadvantages of Carbon Fibre |

| Carbon fibre reduces vehicle weight. This increases acceleration, speed, and fuel. This is because the vehicle becomes less heavy and energy-consuming. | Expensive manufacturing processes make it unsuitable for budget-friendly vehicles. This leads to high production costs and limits its use in more affordable models. |

| It boasts an excellent strength-to-weight ratio. Five times stronger than steel. Both are durable and lightweight, improving the handling and safety aspects. | Carbon fibre is non-recyclable. This poses an environmental concern because it contributes to increased waste. |

| Carbon fibre promises long-term performance. It provides guaranteed strength that is retained. Meanwhile, it effectively resists corrosion and other environmental factors. | It tends to crack or shatter under high-impact forces. Therefore, a specialised form of repair can be costly and intricate. |

| It improves safety by effectively absorbing energy. It helps during collisions, providing better crash protection than other materials. | The limiting factors include production constraints and cost barriers. The vast production costs make it impractical to be a standard material for all vehicles. |

| Carbon fibre parts require less maintenance. It is because they are more substantial. It is also more challenging to get damaged than other materials. | The entire production process of carbon fibre creates a massive carbon footprint. This raises environmental implications. |

This section highlights the essential benefits and drawbacks of aluminium in automobile manufacture.

| Advantages of Aluminium | Disadvantages of Aluminium |

| Highly recyclable, reducing waste and promoting environmental sustainability. This is done by allowing the reuse of materials. This minimises the environmental impact. | It is heavier than carbon fibre. Thereby limiting improvements in the performance of the vehicle. Weight reduction would be crucial to achieving speed. |

| Easily shaped, machined, and combined with other materials. It offers flexibility for diverse automotive applications in both structural and aesthetic components. | It has lesser tensile strength than carbon fibre. This makes it less ideal for high-stress applications, as durability and resistance are top priorities. |

| It's naturally rust-resistant and durable in any climate. Thereby helping to maintain integrity and appearance even in unkind conditions. | High thermal conduction proves potentially troublesome in the elimination of excessive heat. Eventually, it leads to overheating components like an engine. |

| Its effectiveness in terms of heat dissipation. It qualifies it for usage in engine and battery parts because it prevents overheating while lengthening life. | It is softer than steel or carbon fibre and easily dented or scratched. It is more vulnerable to aesthetic scars, and it requires much maintenance. |

| It may lose strength over time due to high mechanical or thermal stress. This can compromise the integrity and safety of demanding condition components. |

Carbon fibre offers weight savings but is costly to the environment. Its production is energy-intensive and uses a lot of electricity. Recycling is still challenging and not nearly as efficient. While recycling is being improved through new technologies. Yet, the sustainability of carbon fibre is still relatively lower than that of other materials, such as aluminium.

Aluminium, however, has excellent recyclability. This makes it an extremely sustainable material. Recycling aluminium requires only 5% of the energy that new production does. It is also recyclable indefinitely with no loss in quality. Therefore, it saves energy and ecological conditions against the use of other materials.

Carbon fibre reduces the vehicle's weight to optimise the range of electric vehicles (EVs). The battery has a better energy-to-weight ratio. This makes it last longer than the heavier body and structural components. It also determines the performance of the EV. The high cost serves as a constraint for applying carbon fibre in all versions of EVs

Aluminium is inexpensive and possesses excellent recyclability. The material is not critical in weight. This helps improve the efficiency of the EV without paying for carbon fibre. Aluminium structures can be found in frameworks, body panels, and covers of batteries. This enhances the performance obtained along with manufacturing flexibility.

Carbon fibre is widely used in high-performance vehicles. Sports cars and luxury models are based on excellent strength-weight ratios. It improves speed and handling. Therefore, reducing weight enables faster acceleration and braking. However, the cost is too high while manufacturing. This makes them inappropriate for budget-conscious, mass-produced cars.

Meanwhile, aluminium may represent an economic optimum for performance in terms of price. While it is lighter than steel, it saves fuel consumption without being as pricey as carbon fibre. Its inherent flexibility makes it easy to shape. So, it is the material most car manufacturers favour for volume production.

In summary, carbon fibre and aluminium have values in the auto-making field. Each material comes with a unique advantage. The case for carbon fibre will focus more on high-performance autos. It is due to its ideal weight-to-strength ratio.

This promotes more incredible speed, improved handling, and more efficient production of autos. However, aluminium is used to balance performance, price, and recyclability. Very importantly, both materials serve significantly in modern car designs.

Carbon fibre would be a much better strength to weight. Thus, it is only practical for high-performance or luxury cars because of the price.

Carbon fibre would be a much better strength to weight. Thus, it is only practical for high-performance or luxury cars because of the price.

Although it is not as strong in terms of tensile or fatigue resistance, the durability of aluminium is significant.

Although it is not as strong in terms of tensile or fatigue resistance, the durability of aluminium is significant.

Aluminium is more sustainable because it is very recyclable. At the same time, carbon fibre is not very sustainable.

Aluminium is more sustainable because it is very recyclable. At the same time, carbon fibre is not very sustainable.

Yes, hybrid composites are created with the best carbon fibre and aluminium. This refers to aluminium-carbon fibre composites or "Al-CFRP" (aluminium-carbon fibre reinforced polymer).

Yes, hybrid composites are created with the best carbon fibre and aluminium. This refers to aluminium-carbon fibre composites or "Al-CFRP" (aluminium-carbon fibre reinforced polymer).

Carbon fibre needs complex and energy-intensive manufacturing processes. Meanwhile, aluminium is more straightforward to produce and is less expensive.

Carbon fibre needs complex and energy-intensive manufacturing processes. Meanwhile, aluminium is more straightforward to produce and is less expensive.

Carbon fibre is used barely in mass-market cars because it is costly and hard to recycle. Thus, it is inapplicable to a mass-market car.

Carbon fibre is used barely in mass-market cars because it is costly and hard to recycle. Thus, it is inapplicable to a mass-market car.

Carbon fibre would be a much better strength to weight. However, it is only practical for high-performance or luxury cars because of the price.

Carbon fibre would be a much better strength to weight. However, it is only practical for high-performance or luxury cars because of the price.

The disadvantages are that they are expensive to manufacture and very difficult to recycle. They break easily under high impact.

The disadvantages are that they are expensive to manufacture and very difficult to recycle. They break easily under high impact.

Aluminium offers good safety features. However, it is more prone to dents and less resistant to specific impacts than other materials.

Aluminium offers good safety features. However, it is more prone to dents and less resistant to specific impacts than other materials.

Carbon fibre is indeed used in automobile car panels. However, such uses can only be practical with high-performance or luxury automobiles.

Carbon fibre is indeed used in automobile car panels. However, such uses can only be practical with high-performance or luxury automobiles.

Aluminium reduces vehicle weight. This improves fuel efficiency by requiring less energy to move the vehicle.

Aluminium reduces vehicle weight. This improves fuel efficiency by requiring less energy to move the vehicle.

Recycling carbon fibre is challenging because of its complex structure. It makes it difficult and expensive to repurpose compared to aluminium.

Recycling carbon fibre is challenging because of its complex structure. It makes it difficult and expensive to repurpose compared to aluminium.

Yes, aluminium is more cost-effective than steel. It is for specific applications like lightweight vehicle parts. However, it can be more expensive for particular applications.

Yes, aluminium is more cost-effective than steel. It is for specific applications like lightweight vehicle parts. However, it can be more expensive for particular applications.

Aluminium is commonly used for body panels, engine parts, and frames. It provides a balance of strength and lightweight properties.

Aluminium is commonly used for body panels, engine parts, and frames. It provides a balance of strength and lightweight properties.